10 Inspiring Sustainable Supply Chain Examples: Leading Companies Paving the Way

Patricia Bernal

Feb 18, 2025

Understanding the Evolution of Supply Chain Sustainability

Over the past decade, supply chain sustainability has grown from a narrow environmental focus into something much broader. Companies now understand that building sustainable supply chains means looking at the whole picture - protecting the environment while also supporting communities and maintaining profitability. This balanced approach recognizes that the health of our planet and the wellbeing of people are deeply connected.

Key Drivers of the Shift

Several important factors have pushed sustainability to the forefront. More consumers are demanding products made responsibly, while new regulations require better environmental practices. Companies have also discovered that sustainable operations often lead to cost savings and reduced risks. Recent supply chain disruptions from extreme weather events have made it clear that adapting to climate change is now essential for business success.

Current State of Supply Chain Sustainability

While awareness has increased, many companies still struggle to fully embrace sustainable practices. Research shows that only 46% of businesses audit their suppliers' sustainability practices, and just 25% actively work with suppliers on improvements. Learn more about supply chain sustainability metrics. This reveals a significant gap between good intentions and real action that needs to be addressed through better transparency and collaboration.

Sustainable Supply Chain Examples: Leaders in Action

Some companies are showing what's possible through strong sustainability programs. Patagonia and IKEA have made sustainability central to how they operate - from using organic materials to ensuring fair wages throughout their supply chains. Their success proves that being environmentally and socially responsible can drive business growth while inspiring positive change across industries.

Challenges and Opportunities

Creating truly sustainable supply chains isn't easy. Companies must trace materials across complex global networks, verify ethical labor standards, and invest in new technologies. However, these challenges also create opportunities. Smart businesses are finding ways to reuse materials, reduce waste, and build stronger relationships with suppliers. This focus on sustainability and resilience helps companies cut costs while preparing for future supply chain demands.

The Business Case for Sustainable Supply Chains

Smart businesses are discovering that sustainable supply chains deliver both environmental and financial benefits. The evidence shows that reducing waste and improving efficiency leads to stronger profits, while meeting growing consumer demand for responsibly-made products.

Profitability Through Sustainability

Companies can achieve significant cost savings through sustainable practices. Simple changes like recycling materials, optimizing energy use, and improving transportation routes directly reduce expenses. Many businesses are finding that closed-loop systems - where materials get reused in production - cut raw material costs substantially while lowering their environmental impact.

Consumer preferences are also driving revenue growth. More shoppers actively seek out eco-friendly products and will pay extra for items made responsibly. This creates real market opportunities for companies that prioritize sustainable sourcing and production.

The numbers back this up. According to a recent DNV Report on Supply Chain Sustainability, 40% of businesses saw revenue growth from sustainability programs, while 34% reduced costs. Looking ahead, 38% expect higher revenues and 40% project additional cost savings next year. These results show that sustainability helps both planet and profits.

Building a Strong Business Case

To create an effective sustainability plan, start by mapping your entire supply chain operations. Look for specific areas where changes could improve efficiency and reduce environmental effects. Review everything from raw material sourcing to final product delivery.

Begin with "quick wins" - projects that deliver fast results in both cost savings and environmental benefits. For example, installing efficient lighting in warehouses or finding shorter delivery routes can quickly reduce expenses and emissions. Early successes help prove the value to stakeholders.

You might be interested in: How the circular economy is transforming the sustainable future.

Measuring and Communicating Value

Clear metrics are essential for tracking sustainability progress. Monitor key indicators like:

Reductions in greenhouse gas emissions

Water usage improvements

Waste reduction

Ethical sourcing compliance

Sharing these results helps demonstrate ROI to investors, customers and partners. Companies that effectively measure and communicate their sustainable supply chain improvements often see stronger brand reputation and competitive advantages. Real-world examples of successful sustainable supply chains provide valuable models for other businesses to follow.

Leading Companies Setting New Standards in Sustainability

The most successful businesses today show that environmental responsibility and profitability can work together. Let's look at how some major companies are making their supply chains more sustainable while maintaining strong business performance.

IKEA: A Circular Economy Vision

IKEA, the Swedish furniture company, has made sustainability central to its operations. They're working to use 100% recycled or renewable materials by 2030. Their furniture buy-back program lets customers return used items for store credit, keeping products in use longer. They've also started furniture rental services in some markets, testing new ways to reduce waste.

Patagonia: Transparency and Traceability

Patagonia shows how a company can put environmental values first. They track their materials from source to store and ensure fair treatment of workers. Their use of organic cotton and recycled fabrics has cut their environmental impact. The company actively encourages customers to repair clothing rather than replace it. They even run campaigns telling people to buy less - putting planet over profit.

Ford: Driving Towards Electric and Ethical Sourcing

Ford Motor Company is changing how car companies think about sustainability. They've invested billions in electric vehicle production to reduce reliance on fossil fuels. The company carefully monitors their battery mineral suppliers to prevent human rights issues and environmental damage. Ford also uses recycled materials in their vehicles and has created systems to reuse old batteries.

Sustainable Supply Chains Across Industries

Major brands are proving that good business and sustainability go hand in hand. Companies like Danone and Nestlé have set clear goals to cut greenhouse gas emissions and increase renewable energy use. Their success shows that sustainable practices work in any industry. Read more examples in this overview of top sustainable supply chains.

Building a Sustainable Future

These companies demonstrate how to balance daily operations with long-term environmental goals. They're creating a path for others to follow while staying profitable. See how companies can work together for sustainability in our article about Sharpei and Nonotu's partnership.

Key Strategies for Sustainable Supply Chain Management

The companies above use several key approaches to improve their supply chains:

Smart Sourcing: Using recycled, renewable and ethically-sourced materials

Product Lifecycle: Making items that last longer and can be repaired or recycled

Supply Chain Visibility: Tracking materials from start to finish to ensure ethical practices

Partner Relationships: Working with suppliers to improve sustainability

Data and Analytics: Using technology to reduce waste and improve efficiency

Clear Communication: Keeping customers and investors informed about sustainability efforts

These practical steps help build supply chains that work better for both business and the environment. When companies commit to these practices, they create lasting positive change while maintaining strong financial performance.

Navigating Stakeholder Expectations and Pressure

Businesses face growing demands to make their supply chains more sustainable. Different groups - from investors to customers to regulators - each bring their own set of expectations. Success requires more than just reacting to these pressures. Companies need to actively engage with stakeholders and find ways to turn their demands into opportunities for growth.

Understanding Stakeholder Concerns

Each stakeholder group brings unique priorities to supply chain sustainability. Investors now look closely at environmental, social, and governance (ESG) performance, seeing poor practices as financial risks. Customers pay more attention to the ethics and environmental impact of their purchases, pushing brands to be more transparent. Regulators continue to roll out new rules around climate change and social issues, requiring businesses to update their practices. These combined pressures create both hurdles and possibilities for improvement.

Responding to Investor Demands

Investor influence drives major changes in supply chain practices. Research from the Council of Supply Chain Management Professionals shows investor pressure for sustainability grew by 25% in five years. Companies can address these concerns by:

Including sustainability data in financial reports

Showing how sustainable practices benefit the bottom line

Keeping investors updated on sustainability progress

Meeting Customer Expectations

Consumers want products that align with their values - made with eco-friendly materials, ethically sourced, and delivered with minimal environmental impact. Smart companies build customer loyalty by:

Offering sustainable product options

Being open about their sustainability efforts

Creating ways for customers to participate through recycling or carbon offset programs

Adapting to Regulatory Requirements

New laws and standards for emissions, waste, and labor practices keep emerging worldwide. Companies must:

Stay informed about current and upcoming regulations

Work proactively with regulators to shape sensible policies

View compliance as a chance to improve operations and reputation

Turning Pressure Into Advantage: Sustainable Supply Chain Examples

Leading businesses show how meeting stakeholder demands can drive positive change. By making sustainability central to operations, these companies reduce costs, attract top talent, build stronger brands, and develop better products and services. Their successes inspire others to see sustainability not as a burden, but as a path to better business results.

Building Your Sustainable Supply Chain Strategy

A sustainable supply chain does more than just benefit the environment - it strengthens your business from the ground up. Let's explore how to create an effective sustainability strategy that delivers real results while supporting both environmental and social responsibility.

Assessing Your Current Operations

Start by mapping out your entire supply chain to understand your current impact. Look at each stage - from where you source materials to how products reach customers. Pay special attention to:

Energy usage hotspots

Areas generating significant waste

Potential labor practice concerns

Transportation inefficiencies

Resource consumption patterns

This initial assessment provides the foundation for making targeted improvements.

Identifying High-Impact Opportunities

After mapping your operations, focus on changes that will make the biggest difference. Some effective starting points include:

Installing LED lighting in warehouses

Optimizing delivery routes

Reducing packaging waste

Improving inventory management

Implementing recycling programs

These "quick wins" build momentum while delivering measurable benefits.

Developing a Comprehensive Sustainability Roadmap

Create specific, measurable goals for key areas like:

Reducing greenhouse gas emissions by X% by [date]

Cutting waste to landfill by X% annually

Improving water efficiency by X% across operations

Achieving X% sustainable sourcing by [date]

Include clear strategies and key performance indicators (KPIs) to track progress toward each goal.

Engaging Suppliers and Measuring Progress

Success requires strong supplier partnerships. Support your suppliers through:

Clear sustainability requirements and expectations

Training on sustainable practices

Incentives for environmental improvements

Regular performance reviews

Open communication channels

Track progress using your established KPIs and share results transparently with stakeholders.

Overcoming Implementation Challenges

Common hurdles include supplier resistance, tracking difficulties across global networks, and upfront costs. Address these by:

Building strong supplier relationships

Investing in supply chain visibility tools

Taking an incremental approach

Focusing on long-term ROI

Learning from industry best practices

Check out our guide on what is recommerce and the future of sustainable consumption for more insights.

Maintaining Momentum and Achieving Long-Term Success

Make sustainability part of your company culture by:

Training employees on sustainable practices

Recognizing and rewarding improvements

Regularly updating goals and strategies

Sharing successes across the organization

Staying current with industry developments

Remember that sustainability is an ongoing journey. Regular review and adjustment of your approach ensures continued progress toward both environmental and business goals.

Future Trends and Strategic Recommendations

Businesses need new approaches to build sustainable supply chains. Key factors driving this change include technological progress, rising consumer awareness, and stricter environmental regulations. Organizations that adapt effectively will gain advantages in markets that increasingly value sustainability.

Emerging Technologies and Innovations

New technologies are reshaping how companies manage sustainable supply chains. Blockchain allows businesses to track products from source to consumer, helping verify ethical practices and prevent counterfeiting. AI and machine learning help optimize shipping routes, predict demand patterns, and cut waste. For example, AI analysis can identify ways to reduce fuel use and emissions in transportation. IoT sensors enable real-time monitoring of environmental conditions, energy usage, and product quality - helping companies spot and fix issues before they grow.

Evolving Best Practices

Companies are adopting new approaches beyond just technology. More businesses now follow circular economy principles - focusing on reuse, repair and recycling to minimize waste. This includes designing products that can be easily taken apart and using recycled materials in manufacturing. We're also seeing more partnerships between companies, suppliers and even competitors working together on sustainability goals. These joint efforts help manage resources better and create shared industry standards.

Future Challenges and Opportunities

Some key challenges remain unsolved. Complex global supply networks make it hard to track sustainability across multiple supplier tiers. The lack of standard metrics makes it difficult to compare performance between organizations. However, these gaps create chances for innovation. Companies that build strong data systems can stand out by clearly showing their sustainability results.

Strategic Recommendations for Building Sustainable Supply Chains

Focus on Transparency: Create systems to track materials and products, share information openly, and confirm ethical sourcing

Adopt New Technology: Use blockchain, AI, and IoT to improve logistics, reduce waste, and meet sustainability goals

Build Partnerships: Work with suppliers, industry groups and peers to solve shared challenges

Design for Circularity: Make products durable, repairable and recyclable to cut waste

Track and Share Results: Monitor key metrics like emissions, water use and waste, and report progress openly

Companies that follow these recommendations can build supply chains that protect the environment while supporting business growth.

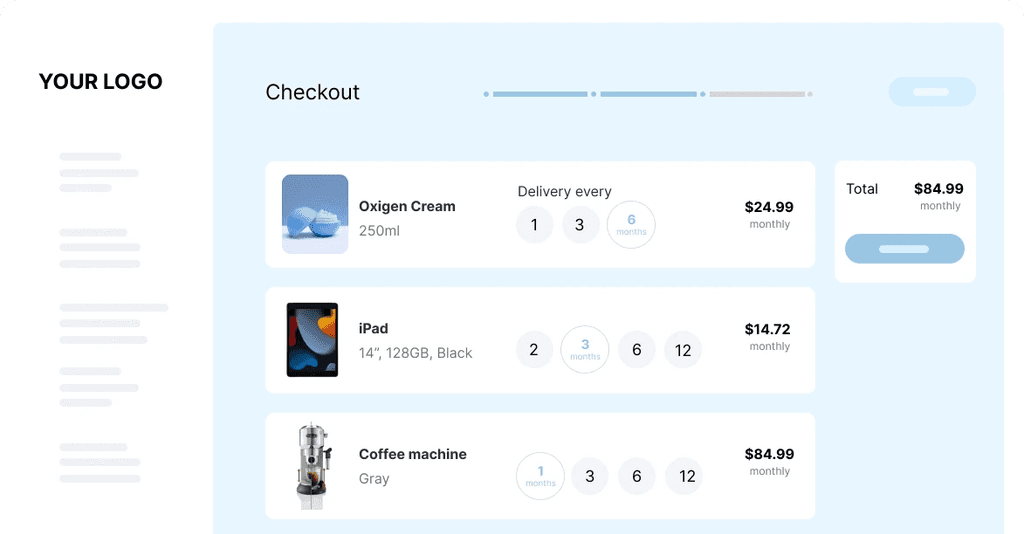

Sharpei helps businesses become more sustainable through circular economy solutions. Our platform enables companies to offer rentals, lease-to-own options, and subscriptions - extending product life and reducing waste. Learn how Sharpei can help your business build a sustainable future.

Related posts

Ready To Join The Circular Movement?

United for a smarter shopping experience and a better planet