8 Top Circular Economy Business Models

Patricia Bernal

Apr 9, 2025

Reimagine Business: The Rise of Circular Models

Sustainability is no longer optional; it's essential for business success. This listicle presents eight circular economy business models offering powerful solutions for a more resilient and profitable future. Discover how Product-as-a-Service, Product Life Extension, Resource Recovery, Sharing Platforms, Circular Supplies, Industrial Symbiosis, Digital Platforms, and Product Redesign can help your business reduce waste, optimize resources, and unlock new revenue streams. Learn how to embrace circularity and gain a competitive edge.

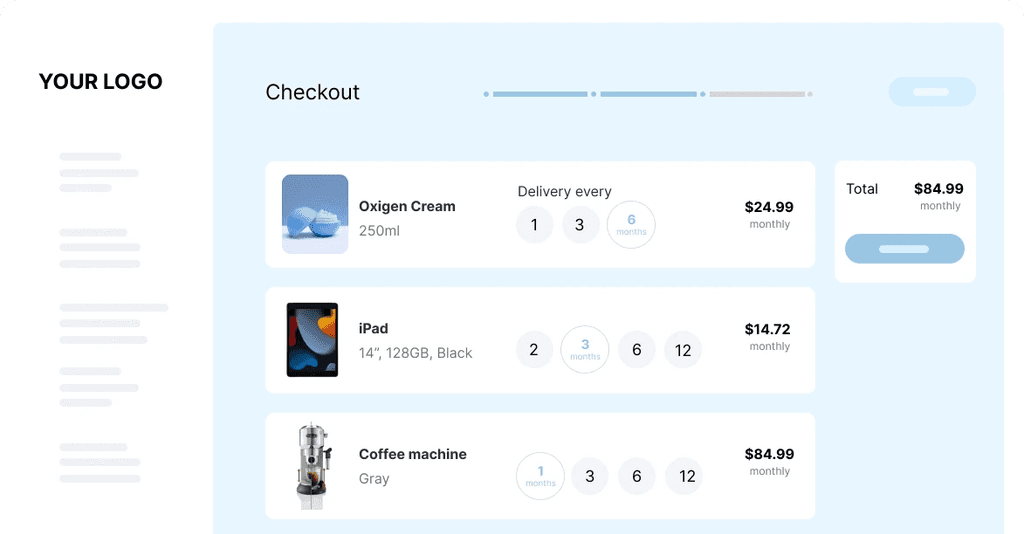

1. Product-as-a-Service (PaaS)

Product-as-a-Service (PaaS) is a revolutionary business model that disrupts the traditional linear economy of "make, take, dispose." Instead of selling products outright, businesses offer customers access to products through rental, lease, or pay-per-use arrangements. The crucial difference is that the company retains ownership of the product. This seemingly simple shift has profound implications for both businesses and the environment. By maintaining ownership, companies are incentivized to design for durability, repairability, and resource efficiency, as they are directly responsible for the product's lifecycle. This fosters a closed-loop system where products are designed for multiple life cycles, dramatically reducing waste and resource consumption.

This model fundamentally changes the relationship between businesses and customers. It moves away from transactional exchanges towards ongoing service relationships. Instead of simply selling a product, businesses provide a continuous service that ensures the customer has access to the functionality they need. This creates a win-win situation: customers get the benefits of using the product without the burdens of ownership, and businesses generate recurring revenue streams and build stronger customer relationships.

Several features distinguish the PaaS model: the shift from ownership to usage-based access, the provider's retained ownership and responsibility, revenue generation through service contracts instead of one-time sales, closed-loop product design, and the fostering of strong customer relationships through ongoing service interactions. Learn more about Product-as-a-Service (PaaS) to understand the nuances of its implementation.

Numerous companies have successfully implemented PaaS. Philips Lighting offers 'Light as a Service' for commercial buildings, where they manage the lighting infrastructure and charge clients for the service of illumination. Rolls-Royce pioneered 'Power by the Hour' for jet engines, charging airlines per hour of engine operation. Even clothing companies like Mud Jeans have embraced the model with their 'Lease A Jeans' subscription. Xerox's document management services, which include printer leasing, and Michelin's 'Tires as a Service' for commercial fleets are further examples of the diverse applications of PaaS.

Pros:

Recurring Revenue Streams: Creates predictable and stable income for businesses.

Product Longevity & Quality: Incentivizes durable and high-quality product design.

Reduced Resource Consumption: Promotes efficient product utilization and minimizes waste.

Enhanced Customer Loyalty: Fosters long-term relationships through ongoing service.

Valuable Product Usage Data: Provides insights for innovation and product improvement.

Cons:

High Upfront Investment: Requires significant capital for product development and infrastructure.

Complex Logistics: Managing maintenance, repair, and product recovery can be challenging.

Cultural Resistance: Overcoming consumer preference for ownership can be difficult in some markets.

Complex Revenue Recognition: Accounting for service-based revenue requires careful planning.

Potential Liability: Retaining product ownership can increase liability risks.

Tips for Implementation:

Start Small: Begin with pilot projects in receptive market segments.

Design for Serviceability: Prioritize durability, repairability, and easy monitoring in product design.

Robust Tracking Systems: Implement systems to manage product lifecycles and maintenance schedules.

Model Cash Flow Carefully: Account for delayed revenue realization compared to traditional sales.

Build Service Expertise: Invest in service capabilities alongside manufacturing expertise.

PaaS deserves its place on this list because it represents a fundamental shift towards a more sustainable and circular economy. By aligning business incentives with resource efficiency and product longevity, PaaS offers a powerful path towards a future where waste is minimized and resources are used more effectively. This model is particularly appealing to e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and businesses seeking new avenues for growth. It offers a compelling value proposition for both businesses and customers, driving both economic and environmental benefits.

2. Product Life Extension

Product Life Extension focuses on maximizing the usable life of products, delaying their eventual disposal and minimizing waste. This model goes beyond simply creating durable goods; it encompasses design strategies, maintenance programs, repair services, remanufacturing, and upgrades that collectively contribute to a longer product lifespan. By keeping products in circulation for longer, businesses reduce the demand for virgin resources, lessen their environmental impact, and potentially unlock new revenue streams through aftermarket services, fostering stronger customer relationships beyond the initial point of sale. This approach represents a significant shift from the traditional linear "take-make-dispose" model towards a more circular and sustainable approach.

Several key features define Product Life Extension initiatives: designing products for durability, repairability, and upgradeability from the outset; implementing comprehensive maintenance and repair programs; offering refurbishment and remanufacturing services for returned or used products; creating modular designs that allow for easy component replacement; and establishing take-back systems to efficiently manage end-of-life products. For example, designing a product with easily replaceable batteries, offering extended warranties, and providing repair manuals empowers consumers to extend the life of their purchase. Learn more about Product Life Extension and the growing recommerce market it helps create.

Companies successfully implementing Product Life Extension strategies demonstrate the model's potential. Patagonia's Worn Wear program repairs and resells used clothing, reducing waste and fostering brand loyalty. Fairphone produces modular smartphones designed for easy repair and upgrades, empowering users to maintain their devices for years. Caterpillar remanufactures heavy equipment, offering a cost-effective alternative to purchasing new machinery. Even tech giants like Apple offer certified refurbishment programs, giving older devices a second life. DeWalt’s tool rebuild services similarly extend the life of professional-grade tools.

Pros:

Reduced environmental impact: Less raw material consumption and waste generation contribute to a smaller environmental footprint.

New revenue streams: Aftermarket services like repairs, upgrades, and remanufacturing create new revenue opportunities.

Enhanced brand loyalty: Long-term product relationships foster stronger customer loyalty and positive brand perception.

Lower total cost of ownership: Extending product lifespan often reduces the overall cost for customers compared to frequent replacements.

Competitive differentiation: Sustainability and product longevity can be powerful differentiators in competitive markets.

Cons:

Cannibalization of new product sales: Extending the lifespan of existing products might reduce demand for new ones.

Design and production adaptations: Requires upfront investments in design changes and potentially more complex production methods.

Reverse logistics complexity: Managing product returns, repairs, and remanufacturing requires robust reverse logistics systems.

Technological obsolescence: Rapidly evolving technology standards can present challenges for long-term product support.

Higher initial production costs: Designing for durability and repairability can sometimes increase initial manufacturing costs.

Tips for Implementation:

Design with the end in mind: Incorporate repair and upgrade considerations into the initial design stage.

Streamline reverse logistics: Establish efficient systems for product returns and servicing.

Empower customer service: Train customer service teams to effectively support repair and maintenance inquiries.

Set quality standards: Create clear standards for product refurbishment and remanufacturing to ensure consistent quality.

Communicate the value proposition: Clearly communicate the economic and environmental benefits of Product Life Extension to customers.

Product Life Extension deserves a place on this list because it represents a fundamental shift towards a more sustainable and circular economy. By prioritizing product longevity, businesses can minimize waste, build stronger customer relationships, and unlock new business opportunities while contributing to a healthier planet. This model is particularly relevant for e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and any business seeking growth within a framework of environmental responsibility.

3. Resource Recovery

Resource Recovery focuses on extracting value from waste streams, transforming what was once considered trash into valuable resources. This model operates by recovering and repurposing materials, energy, or biological components from end-of-life products, by-products, and manufacturing waste. Instead of viewing waste management as a cost center, resource recovery reframes it as a potential profit center, simultaneously reducing environmental impact and securing access to valuable materials. This approach is a cornerstone of the circular economy, moving away from the traditional linear "take-make-dispose" model.

Resource recovery encompasses a range of strategies, including upcycling waste into higher-value applications, processing biological waste into nutrients or energy (like compost or biogas), and establishing industrial symbiosis where one company's waste becomes another's input. Closed-loop systems represent the pinnacle of this model, where recovered materials are reincorporated directly back into the production process. This reduces the need for virgin materials and minimizes waste generation. For example, businesses dealing with substantial organic waste might explore composting or anaerobic digestion to comply with regulations like California's SB 1383 compliance, which mandates organic waste reduction, and potentially generate revenue from the resulting compost or biogas.

Examples of Successful Resource Recovery:

TerraCycle: Offers recycling programs for a wide range of difficult-to-recycle waste, partnering with brands to create collection and processing systems.

Interface: Their ReEntry program recovers materials from used carpet tiles, recycling them back into new products.

Veolia: Operates waste-to-energy facilities, converting non-recyclable waste into electricity and heat.

Apple: Employs the Daisy robot for iPhone disassembly and material recovery, maximizing the reuse of valuable components.

Kalundborg Symbiosis: An industrial ecosystem in Denmark where companies exchange by-products and waste streams, creating a closed-loop system.

Tips for Implementing Resource Recovery:

Analyze Material Flows: Conduct thorough analyses to identify potential recovery opportunities within your operations and supply chain.

Design for Recovery: Consider material recovery from the outset of product design, choosing materials that are easily recyclable or reusable.

Build Partnerships: Develop partnerships across industries to create material exchange networks and identify synergistic opportunities.

Invest in Technology: Explore technologies that improve separation and processing efficiency, such as automated sorting and advanced recycling techniques.

Lifecycle Assessment: Evaluate the full lifecycle environmental impact of recovery processes, ensuring that the benefits outweigh any potential drawbacks.

Pros of Resource Recovery:

Reduced landfill waste and associated disposal costs.

Creation of new revenue streams from previously discarded materials.

Decreased dependency on virgin material extraction, lowering environmental impact.

Potential reduction in overall manufacturing costs through the use of cheaper recovered materials.

Increased resilience against material price volatility and supply disruptions.

Cons of Resource Recovery:

Often requires significant upfront investment in infrastructure and technology.

May face regulatory hurdles related to waste handling and processing.

Quality of recovered materials can be inconsistent, requiring additional processing or blending with virgin materials.

Collection logistics can be complex and costly, particularly for dispersed waste streams.

May necessitate changes to existing manufacturing processes to accommodate recovered materials.

Resource recovery offers a powerful approach for businesses seeking to embrace circularity, achieve sustainability goals, and unlock new economic opportunities. By strategically implementing resource recovery initiatives, businesses can minimize their environmental footprint, enhance their brand reputation, and gain a competitive advantage in an increasingly resource-constrained world. This model is particularly relevant for e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and businesses seeking growth and innovation through sustainable practices.

4. Sharing Platforms

Sharing platforms represent a powerful business model within the circular economy, focusing on maximizing the utilization of existing products rather than producing more. They operate by connecting owners of underused assets with individuals who need temporary access to those assets. This facilitates a shift away from individual ownership towards shared usage, thereby reducing the overall demand for new products and minimizing the environmental impact associated with production. Digital platforms are the backbone of this model, enabling seamless connections and transactions between users. This approach not only benefits the environment but also opens up new revenue streams for businesses and provides consumers with affordable access to a wider range of goods and services.

Sharing platforms function through a combination of key features. These typically include a digital platform (website or app) that connects users, robust search and filtering options, secure payment gateways, rating and review systems to build trust, and often, insurance and maintenance frameworks to protect both owners and users. Asset tracking and management technologies can also play a crucial role, especially for businesses managing larger inventories of shared items.

Successful examples of this model are abundant and demonstrate its versatility across various sectors. Airbnb revolutionized the hospitality industry by connecting travelers with individuals renting out their homes or spare rooms. Turo applies the same principle to car sharing, allowing car owners to earn income from their vehicles while providing renters with a flexible alternative to traditional car rentals. Peerby focuses on hyperlocal sharing, facilitating the exchange of tools and equipment within neighborhoods, while Spinlister caters to the sharing of bikes and other sporting equipment. For professionals, platforms like ShareGrid offer access to high-end camera equipment, making expensive resources more accessible.

When and Why to Use This Approach:

This model is particularly suited for businesses dealing with durable goods that are often underutilized. It's ideal for sectors where ownership costs are high, demand fluctuates, or access rather than ownership is the primary driver for consumers. E-commerce platforms can integrate sharing features to extend the lifespan of products and attract environmentally conscious customers. Retail businesses can offer rental options alongside traditional sales, creating new revenue streams and catering to a broader customer base. For sustainability-conscious brands, sharing platforms align perfectly with their values and provide a tangible way to reduce their environmental footprint.

Tips for Implementing a Sharing Platform:

Prioritize Trust and Security: Implement robust user verification processes, background checks (where applicable), and secure payment gateways. Transparent rating and review systems are crucial for building trust between users.

User-Friendly Interface: Design a simple and intuitive platform that makes it easy for users to list their items, search for available products, and manage transactions.

Clear Policies and Procedures: Establish clear policies regarding damage, maintenance, cancellations, and dispute resolution. This helps prevent misunderstandings and fosters a positive user experience.

Insurance Partnerships: Explore insurance partnerships to protect both owners and users against potential risks, such as damage, theft, or liability.

Data-Driven Optimization: Gather and analyze usage data to understand user behavior, optimize pricing strategies, and improve platform performance.

Pros:

Significantly increases product utilization rates

Reduces total resource consumption

Creates new revenue opportunities with minimal asset investment

Builds community and social connections

Makes premium products accessible to more users

Cons:

Regulatory challenges in certain sectors

Potential liability and insurance complications

Increased wear and tear on shared products

Trust and security concerns

Potential resistance from traditional business models

Sharing platforms deserve their place on this list because they represent a fundamental shift in consumption patterns, moving away from individual ownership towards shared access. This model offers a compelling pathway towards a more sustainable and equitable future, benefitting businesses, consumers, and the environment alike.

5. Circular Supplies

The Circular Supplies model represents a fundamental shift in how businesses source and utilize materials. Instead of relying on the traditional linear "take-make-dispose" model, it prioritizes bio-based, renewable, or fully recyclable inputs designed to circulate within either technical or biological cycles. This eliminates waste and pollution at the source by designing them out, contributing to the regeneration of natural systems. It is foundational for other circular economy approaches, as many of them rely on access to circularly designed materials.

How it Works:

Circular Supplies focuses on replacing conventional, often single-use or non-recyclable, materials with alternatives that can be continually reused or safely returned to the environment. This involves:

Sourcing renewable and recyclable materials: Prioritizing inputs like bioplastics, mycelium, recycled plastics, and other materials that can be perpetually cycled.

Designing for disassembly and reuse: Products are engineered for easy separation of components and materials, facilitating repair, refurbishment, and remanufacturing.

Eliminating toxic substances: Hazardous materials are phased out and replaced with safe, biocompatible alternatives.

Standardizing materials: Promoting the use of standardized materials simplifies recycling and reprocessing.

Transparent supply chains: Implementing robust tracking and certification systems to ensure the origin and circularity of materials.

Examples of Successful Implementation:

Ecovative: Creates packaging materials from mycelium, the root structure of mushrooms, offering a compostable alternative to Styrofoam.

Novamont: Produces Mater-Bi, a family of biodegradable and compostable bioplastics used in various applications, from packaging to agriculture.

Interface: Manufactures carbon-negative carpet tiles using recycled and bio-based materials, showcasing how a large manufacturer can embrace circularity.

C2C-certified products: Various manufacturers offer Cradle to Cradle Certified™ products, indicating adherence to strict circularity standards.

Growdeck: Uses recycled plastic to create a growing medium for hydroponics, diverting waste and providing a sustainable alternative to traditional growing media.

Why Circular Supplies Matters:

This model deserves its place on the list because it addresses the root cause of much of our environmental impact: resource depletion and waste generation. By transitioning to circular supplies, businesses can:

Reduce dependence on finite resources: Lessening pressure on virgin material extraction and preserving natural ecosystems.

Eliminate end-of-life waste management challenges: Reducing landfill waste and the associated environmental costs.

Create products compatible with other circular business models: Enabling product-as-a-service, sharing platforms, and other circular strategies.

Reduce compliance costs related to hazardous materials: Avoiding penalties and expenses related to handling and disposal of toxic substances.

Appeal to environmentally conscious consumers: Meeting growing consumer demand for sustainable and responsible products.

Pros:

Reduced dependence on finite resources

Elimination of end-of-life waste management challenges

Creation of products compatible with other circular business models

Reduced compliance costs related to hazardous materials

Appeal to environmentally conscious consumers

Cons:

Often higher initial material costs

May require redesign of products and processes

Limited availability of some circular materials at scale

Potential performance trade-offs compared to conventional materials

Complex certification and verification processes

Actionable Tips for Implementation:

Start with material assessments: Analyze the composition of your current products to identify opportunities for substitution.

Prioritize materials based on impact and feasibility: Focus on materials with the highest environmental impact and where circular alternatives are readily available.

Partner with innovative material suppliers: Collaborate with companies developing and producing circular materials.

Consider the full lifecycle impact: Evaluate the environmental footprint of materials throughout their entire lifecycle, from extraction to end-of-life.

Work with suppliers to scale circular material production: Help drive demand and increase the availability of circular materials.

When and Why to Use This Approach:

Circular Supplies is relevant for any business seeking to reduce its environmental footprint and transition to a more sustainable model. It is particularly beneficial for:

E-commerce Merchants: Reducing packaging waste and offering eco-friendly products.

Retail Businesses: Sourcing sustainable products and minimizing waste throughout their operations.

Sustainability-Conscious Brands: Demonstrating commitment to environmental responsibility and attracting eco-minded consumers.

Tech-Savvy Companies: Integrating innovative materials and technologies to create cutting-edge sustainable products.

Businesses Seeking Growth: Differentiating themselves in the market and capturing the growing demand for circular products and services.

This model is inspired and popularized by the work of William McDonough and Michael Braungart (Cradle to Cradle), The Ellen MacArthur Foundation, Gunter Pauli (Blue Economy), Cradle to Cradle Products Innovation Institute, and Ray Anderson (Interface founder). While there is no single website encompassing all these resources, searching for these individuals and organizations will provide further valuable insights.

6. Industrial Symbiosis

Industrial Symbiosis represents a powerful circular economy model where businesses collaborate to share resources, transforming what would be waste for one into valuable inputs for another. This creates a network of interconnected organizations that function like an ecosystem, reducing their collective environmental footprint while simultaneously unlocking economic benefits. It's a win-win approach that fosters both sustainability and profitability.

How it Works:

Industrial Symbiosis hinges on the concept of inter-company resource exchange networks. Companies within a defined geographic area, often an industrial park or region, identify opportunities to exchange materials, energy, water, and by-products. For instance, the waste heat from a power plant could be used to heat a nearby greenhouse, or the by-product of a manufacturing process could become the raw material for another company. This closed-loop system minimizes waste disposal costs and reduces reliance on virgin resources. Features of a successful symbiosis network include:

Inter-company resource exchange networks: Formal and informal agreements for resource sharing.

Waste streams repurposed as valuable inputs: Shifting the perspective of waste from a cost to a resource.

Geographic clustering of complementary businesses: Facilitating efficient physical exchange of resources.

Shared infrastructure and utilities: Optimizing resource use and reducing costs.

Collaborative business relationships and knowledge exchange: Fostering innovation and mutual benefit.

Examples of Successful Implementation:

Several successful examples demonstrate the potential of Industrial Symbiosis:

Kalundborg Symbiosis (Denmark): The archetypal industrial symbiosis park, where multiple companies exchange resources like steam, fly ash, and wastewater.

Ulsan Eco-Industrial Park (South Korea): A large-scale project focusing on by-product exchanges and shared infrastructure.

NISP (National Industrial Symbiosis Programme, UK): A national program facilitating connections and resource exchanges between businesses.

Why Industrial Symbiosis Deserves its Place on the List:

Industrial Symbiosis offers a tangible pathway to a circular economy by directly addressing the issue of waste and resource depletion. It's not just about reducing environmental impact; it's about creating new revenue streams, fostering innovation, and building more resilient businesses. For e-commerce merchants, retail businesses, sustainability-conscious brands, and tech-savvy companies looking for growth opportunities, Industrial Symbiosis presents a powerful framework for achieving both economic and environmental goals.

Pros:

Transforms waste disposal costs into revenue opportunities: Waste becomes a commodity.

Reduces overall resource consumption across the network: Less reliance on virgin materials.

Spreads infrastructure costs across multiple businesses: Shared investment in utilities and facilities.

Builds business resilience through diversified resource streams: Less vulnerability to supply chain disruptions.

Creates opportunities for innovation and new product development: Utilizing by-products for new applications.

Cons:

Requires significant coordination between multiple organizations: Establishing trust and clear agreements is crucial.

Geographic constraints for physical resource exchanges: Proximity is essential for efficient transfer of materials.

Dependency risks if key partner businesses change or relocate: Changes in one business can impact others.

Regulatory challenges crossing waste/product boundaries: Navigating legal definitions and permitting processes.

Requires detailed information sharing about processes and materials: Transparency is key for identifying synergies.

Actionable Tips for Implementation:

Begin with material flow mapping: Identify potential exchange opportunities within your operations and with neighboring businesses.

Start with simple, high-value exchanges: Build complexity gradually.

Develop clear agreements about quality, quantity, and timing of exchanges: Formalize partnerships with contracts.

Consider establishing a coordinating entity to facilitate exchanges: A central organization can streamline communication and logistics.

Engage with regulators early to address potential compliance issues: Proactive communication can avoid delays and complications.

This collaborative approach, popularized by experts like Marian Chertow and Peter Laybourn and championed by organizations like the Ellen MacArthur Foundation and the World Business Council for Sustainable Development, has the potential to revolutionize how businesses operate and contribute to a more sustainable future. By embracing Industrial Symbiosis, companies can move beyond simply minimizing negative impacts and actively contribute to a regenerative and prosperous economy.

7. Digital Platforms for Circular Economy

Digital platforms are rapidly becoming essential tools for implementing circular economy principles. These platforms leverage technology to optimize the flow of materials and products throughout their lifecycle, creating a more sustainable and efficient system. They facilitate the tracking of materials, management of reverse logistics, connection of stakeholders, and overall management of product lifecycles. This approach is crucial for businesses seeking to transition to a circular economy model, offering numerous benefits across various sectors.

How They Work:

Digital platforms for the circular economy utilize a variety of technologies to achieve their goals. These include:

Material passports and digital product information systems: These systems create digital twins of physical products, containing information about their composition, origin, and potential uses at end-of-life. This allows for easier sorting and recovery of valuable materials.

Blockchain for supply chain transparency and material tracking: Blockchain technology provides an immutable record of material flows, enabling greater transparency and accountability throughout the supply chain. This builds trust in the provenance and quality of secondary materials.

IoT for product monitoring and predictive maintenance: Sensors embedded in products can collect data on usage and performance, enabling predictive maintenance and extending product lifespans. This reduces waste and optimizes resource utilization.

Digital marketplaces for secondary materials and products: These platforms connect businesses with suppliers of secondary materials and products, facilitating the reuse and recycling of valuable resources.

Lifecycle management software and analytics: These tools provide businesses with insights into the environmental and economic performance of their products throughout their lifecycle, enabling data-driven decision-making for circularity.

Examples of Successful Implementation:

Madaster platform: Creates material passports for buildings, facilitating the recovery of valuable materials at the end of a building's life.

Excess Materials Exchange: A digital marketplace that connects businesses with suppliers of excess materials, promoting industrial symbiosis and reducing waste.

Provenance blockchain platform: Uses blockchain to track the origin and journey of products, enhancing supply chain transparency and building consumer trust.

CircularTree's BOMcheck: Facilitates material compliance tracking, ensuring products meet regulatory requirements and supporting responsible sourcing.

IBM's Food Trust blockchain: Improves traceability and transparency in food supply chains, reducing food waste and enhancing food safety.

When and Why to Use This Approach:

Digital platforms are particularly valuable for businesses that:

Manage complex supply chains with multiple stakeholders.

Handle large volumes of materials or products.

Seek to increase transparency and traceability in their operations.

Aim to optimize resource utilization and reduce waste.

Want to unlock new business opportunities in the circular economy.

Pros:

Enables traceability of materials throughout their lifecycle.

Reduces transaction costs for circular business models.

Facilitates trust in the quality and provenance of secondary materials.

Provides data for optimizing circular processes.

Scales circular systems by connecting diverse stakeholders.

Cons:

Requires significant digital infrastructure and expertise.

Potential data security and privacy concerns.

Integration challenges with legacy systems.

Technology adoption barriers across supply chains.

Ongoing development costs as technology evolves.

Tips for Implementation:

Start with clear use cases that deliver immediate value.

Ensure user experience is designed for all stakeholders, not just technical users.

Build in data standards that enable interoperability.

Consider hybrid approaches that combine digital and physical verification.

Develop change management strategies to drive platform adoption.

Learn more about Digital Platforms for Circular Economy

This model deserves a prominent place on this list because it represents a fundamental shift in how circular economy principles can be implemented at scale. The power of digital platforms lies in their ability to connect diverse stakeholders, streamline processes, and generate valuable data insights, ultimately driving the transition towards a more sustainable and resource-efficient future. For e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and businesses seeking growth, embracing digital platforms is not just an option, but a crucial step in navigating the evolving landscape of commerce and contributing to a circular economy.

8. Product Redesign

Product Redesign is a fundamental approach to circularity that involves rethinking products from the ground up. It goes beyond making minor improvements and instead focuses on creating products optimized for disassembly, repair, upgradeability, recyclability, and reduced material use, all while maintaining or even enhancing functionality. This makes Product Redesign a cornerstone for various circular business models and unlocks significant value creation opportunities. It's a critical strategy for e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and any business seeking growth in a resource-constrained world.

How it Works:

Product Redesign centers around building circularity principles into the DNA of a product. This involves meticulous planning across the entire product lifecycle, from material sourcing and manufacturing to end-of-life management. Features like modular design, standardized components, and the use of recyclable materials are key elements of this approach.

Features of Circular Product Design:

Design for Disassembly and Easy Component Separation: Products are designed to be easily taken apart, allowing for component recovery and reuse.

Modular Architecture Allowing for Part Replacement: Modularity enables the replacement of faulty or outdated parts, extending the product's lifespan.

Standardized Components Across Product Lines: Using common components across different products streamlines manufacturing, reduces waste, and simplifies repairs.

Material Selection for Recyclability and Regeneration: Prioritizing recycled and recyclable materials minimizes environmental impact and supports a closed-loop system.

Elimination of Toxic Substances and Adhesives that Impede Recycling: Choosing materials and joining methods that don't hinder recycling processes is crucial for effective resource recovery.

Pros:

Addresses Circularity at the Product Creation Stage: Proactively builds circularity into the product's core, minimizing waste from the outset.

Enables Implementation of Other Circular Business Models: Facilitates models like product-as-a-service, remanufacturing, and take-back programs.

Can Reduce Manufacturing Costs Through Standardization: Using standardized components can optimize production processes and reduce material costs.

Improves Product Repairability and Customer Satisfaction: Easier repairs lead to longer product lifespans, increased customer satisfaction, and reduced e-waste.

Creates Opportunity for Brand Differentiation: Demonstrates a commitment to sustainability, resonating with environmentally conscious consumers.

Cons:

May Require Significant Upfront R&D Investment: Redesigning products can involve substantial investment in research, development, and new tooling.

Can Face Internal Resistance to Changing Established Designs: Shifting away from traditional linear design processes can be challenging within organizations.

May Challenge Existing Manufacturing Capabilities: Adopting new materials and assembly methods might require investments in new manufacturing equipment and processes.

Potential Market Resistance to New Product Formats: Consumers might initially hesitate to adopt redesigned products, particularly if they deviate significantly from familiar designs.

Requires Deep Expertise in Materials and Design Methodologies: Successful product redesign necessitates specialized knowledge in materials science, design for disassembly, and lifecycle assessment.

Examples of Successful Implementation:

Fairphone: Offers modular smartphones designed for easy repair and component replacement.

Framework: Produces repairable and upgradeable laptops, empowering users to extend the life of their devices.

Herman Miller: Designs office furniture with disassembly and material recovery in mind.

Gerrard Street: Creates modular headphones with replaceable parts, minimizing waste and maximizing product longevity.

DS Smith: Develops innovative circular packaging designs optimized for recyclability and reuse.

Tips for Implementing Product Redesign:

Conduct lifecycle assessments to identify priority redesign areas: Analyze the environmental impact of your product throughout its lifecycle to pinpoint areas for improvement.

Involve cross-functional teams including marketing, manufacturing, and service: Collaboration across departments ensures a holistic approach to product redesign.

Use design thinking methodologies to reimagine product architecture: Employ design thinking principles to develop innovative and user-centered circular product designs.

Develop standardized components that work across product lines: Standardization streamlines production, reduces waste, and simplifies repairs.

Engage customers in testing and refining circular designs: Gather feedback from users to ensure the redesigned products meet their needs and preferences.

Why Product Redesign Deserves its Place in the List:

In a world grappling with resource depletion and waste management challenges, Product Redesign offers a proactive solution. By embedding circularity principles into the design phase, businesses can minimize their environmental footprint, enhance customer value, and unlock new economic opportunities. This approach is not merely a trend but a necessary evolution in product development for a sustainable future.

Popularized By: William McDonough and Michael Braungart (Cradle to Cradle), Janine Benyus (biomimicry advocate), IDEO design firm, The Ellen MacArthur Foundation, Dieter Rams (influential designer who advocated for sustainable design).

9. Circular Economy Business Models: A Comparison Matrix

Business Model | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases ⭐ | Key Advantages 💡 |

|---|---|---|---|---|---|

Product-as-a-Service (PaaS) | High; complex logistics and lifecycle management | High; requires significant capital and service setup | Recurring revenue and enhanced usage data | Commercial assets and long-life products | Strong customer ties and data-driven innovations |

Product Life Extension | Moderate; requires design changes and repair integration | Moderate; investment in maintenance and refurbishment | Extended product lifespan and waste reduction | Durable goods, electronics, and apparel | Aftermarket revenue and improved brand loyalty |

Resource Recovery | High; involves complex processes and regulatory hurdles | High; needs specialized recovery facilities | New revenue streams and reduced material costs | Industrial sectors with significant waste | Waste minimization and resource optimization |

Sharing Platforms | Moderate; digital platform development with trust systems | Low; minimal investment in physical assets | Increased asset utilization and revenue from access fees | Urban environments and underused asset markets | Maximized efficiency and community engagement |

Circular Supplies | Moderate; requires supply chain redesign and material switching | Moderate to high; sourcing sustainable inputs | Reduced dependency on virgin resources | Manufacturing and eco-conscious products | Sustainable sourcing and enhanced regulatory compliance |

Industrial Symbiosis | High; needs coordinated exchange between multiple entities | Shared; depends on collaboration between partners | Cost savings and efficient resource exchange | Industrial clusters and eco-industrial parks | Collaborative innovation and reduced waste |

Digital Platforms for Circular Economy | High; integration of advanced digital technologies | High; significant digital infrastructure investment | Enhanced transparency and efficient lifecycle management | Supply chain tracking and digital material management | Scalable connectivity and data-driven decisions |

Product Redesign | High; intensive R&D and complete design overhaul | High; substantial investment in redesign and testing | Optimized recyclability and improved repairability | Industries pursuing foundational circularity | Enables circularity and drives brand differentiation |

Embrace the Future: Building a Circular Economy

From Product-as-a-Service and resource recovery to sharing platforms and circular supply chains, the business models explored in this article offer a powerful framework for transitioning to a circular economy. The key takeaway is that circularity isn't just about minimizing waste; it's about rethinking the entire lifecycle of a product or service to create closed-loop systems that maximize value and minimize environmental impact. Mastering these approaches is crucial for businesses seeking to not only mitigate risk in a resource-constrained world, but also unlock new revenue streams, enhance brand reputation, and attract environmentally conscious consumers. By embracing circularity, businesses can foster innovation, drive economic growth, and contribute to a healthier planet. This transition represents a fundamental shift towards a more sustainable and resilient future for all, one where waste is minimized, resources are valued, and prosperity is decoupled from environmental degradation.

Ready to take the next step towards circularity and optimize your product lifecycle management? Explore Sharpei, a platform designed to streamline and automate your circular economy initiatives. Visit Sharpei to learn more and discover how we can help you embrace the future of sustainable business.

Related posts

Ready To Join The Circular Movement?

United for a smarter shopping experience and a better planet