10 Circular Economy Business Models Shaping Future

Patricia Bernal

Apr 10, 2025

Going Green with Circularity: A New Business Era

The circular economy prioritizes resource efficiency and minimizes waste. Want to boost your business and contribute to a sustainable future? This listicle reveals ten key circular economy models to help you gain a competitive edge and reduce your environmental footprint. Discover how Product as a Service, resource recovery, product life extension, sharing platforms, and more can revolutionize your operations. Explore these innovative approaches and start building a greener, more profitable tomorrow.

1. Product as a Service (PaaS)

Product as a Service (PaaS) is a revolutionary business model that flips the traditional concept of product ownership on its head. Instead of selling products outright, businesses offer them as services, charging customers for usage or access rather than ownership. This means the company retains ownership of the product, managing its maintenance, repair, and eventual end-of-life recovery. Customers, on the other hand, enjoy the benefits of using the product without the burdens and responsibilities that come with owning it. This model fundamentally realigns the incentives of both producer and consumer, encouraging durability, efficiency, and product longevity.

This shift towards a service-based approach incentivizes manufacturers to design products for durability and repairability, maximizing their lifespan and minimizing waste. It creates a closed-loop system where the producer is responsible for the entire lifecycle of the product, from design and manufacturing to end-of-life management. This inherent focus on sustainability makes PaaS a crucial element of the circular economy.

Key Features of PaaS:

Ownership Retention: The producer retains ownership of the product.

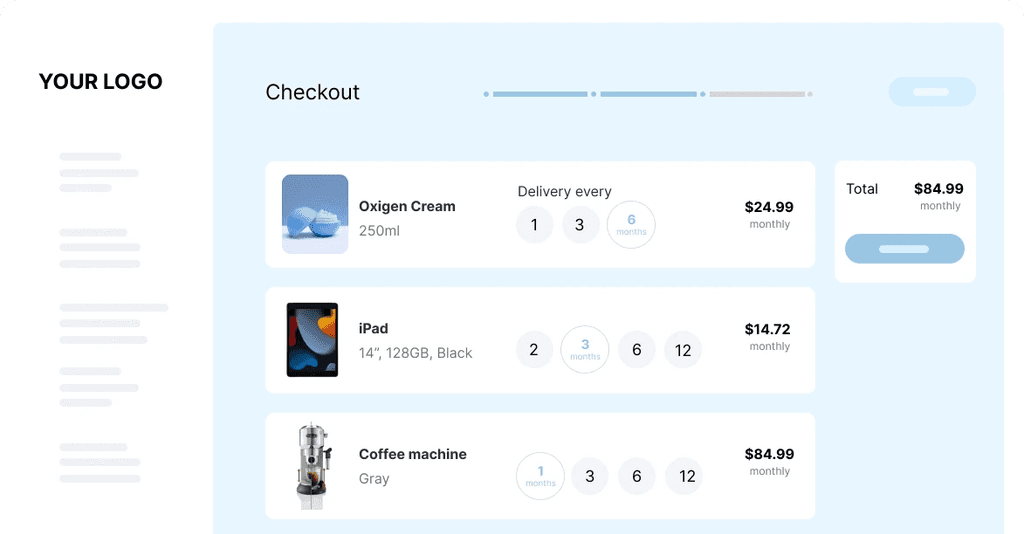

Usage-Based Payment: Customers pay for the use or access to the product, often through subscription models.

Durability and Repairability: Products are designed to last longer and be easily repaired.

Manufacturer-Managed Maintenance: The producer handles all maintenance and repairs.

Resource Efficiency: The model inherently incentivizes resource optimization.

Digital Monitoring and IoT Integration: Often involves digital technologies to track product usage and performance.

Pros of Implementing PaaS:

Recurring Revenue Streams: Creates ongoing revenue streams instead of one-time sales.

Reduced Resource Consumption: Maximizes product utilization and minimizes waste.

Stronger Customer Relationships: Fosters ongoing engagement and builds loyalty.

Valuable Usage Data: Provides data insights for product improvement and innovation.

Alignment with Sustainability: Directly links business profits with environmental responsibility.

Cons of Implementing PaaS:

High Upfront Investment: Requires significant initial capital for product development and infrastructure.

Complex Logistics: Managing maintenance and recovery can be logistically challenging.

Customer Resistance: Some customers may resist subscription models or perceive a loss of control.

Revenue Recognition Complexity: Accounting for revenue can be more complex than traditional sales.

Transition Challenges: Shifting from traditional manufacturing to a service-based model can be difficult.

Examples of Successful PaaS Implementation:

Philips Lighting: Offers 'Light as a Service' for commercial clients, providing lighting solutions without upfront costs.

Rolls-Royce: Provides 'Power by the Hour' jet engine service contracts, charging airlines per hour of engine use.

Michelin: Offers tire-as-a-service for commercial fleets, managing tire maintenance and replacement.

Mud Jeans: Leases denim products to customers, taking them back for recycling at the end of their life cycle.

Xerox: Provides document management services instead of simply selling printers.

Tips for Implementing PaaS:

Start with B2B: Begin with business-to-business markets where service contracts are already common.

Robust Asset Tracking: Implement comprehensive asset tracking systems to manage product lifecycles.

Adapt Financial Models: Design financial models that account for delayed revenue recognition.

Design for Durability and Maintenance: Prioritize product design that supports easy maintenance and component recovery.

Consider Hybrid Models: Explore hybrid models that combine traditional sales with service elements during the transition. Learn more about Product as a Service (PaaS) and how it can be adapted to your specific business needs.

PaaS deserves its place on this list because it represents a fundamental shift towards a more sustainable and circular economy. It offers a compelling alternative to traditional ownership models, aligning business interests with environmental responsibility while creating new opportunities for innovation and growth. By prioritizing resource efficiency, product longevity, and customer relationships, PaaS offers a pathway to a more sustainable future for businesses and the planet.

2. Resource Recovery and Recycling

Resource Recovery and Recycling is a circular economy business model centered around capturing value from materials that would otherwise be considered waste. This approach involves collecting end-of-life products or waste streams and processing them to extract valuable resources that can be used to create new materials or products. The core principle is to minimize waste generation by continuously cycling materials back into production, effectively mimicking natural ecosystems. Instead of a linear "take-make-dispose" model, Resource Recovery and Recycling strives for a closed-loop system, significantly reducing the need for virgin resources.

This model encompasses a range of activities, including material identification and sorting, processing technologies to transform waste into usable resources, and establishing robust supply chain partnerships for securing a consistent flow of waste feedstock. Advanced recycling and upcycling technologies play a crucial role, enabling businesses to extract maximum value from materials that were previously destined for landfills. Learn more about Resource Recovery and Recycling to understand the broader context of resource recirculation.

Companies like TerraCycle exemplify this model through their innovative recycling programs for hard-to-recycle materials. Veolia, a global leader in waste management, demonstrates resource recovery at scale with its extensive operations worldwide. Interface's ReEntry program focuses on recovering and recycling carpet tiles, showcasing the potential for closed-loop systems within specific industries. Other successful examples include MBA Polymers, specializing in recycling plastics from complex waste streams, and Novelis, known for their closed-loop aluminum recycling programs.

This model deserves its place on this list because it addresses a fundamental challenge of the linear economy: waste. By turning waste into a resource, businesses can unlock significant economic and environmental benefits. The key features driving its success include: recovery of materials from diverse waste streams; advanced processing technologies; vertical integration of waste collection and processing; sophisticated material identification and sorting systems; and strategic supply chain partnerships.

Pros:

Reduces dependency on virgin raw materials, lessening the environmental impact of extraction.

Creates value from what was previously considered waste, opening new revenue streams.

Often reduces energy consumption compared to virgin material processing.

Can create significant cost advantages through resource efficiency.

Reduces environmental impacts associated with waste disposal.

Cons:

Quality of recovered materials can be inconsistent, posing challenges for manufacturing.

High initial capital investment for processing facilities can be a barrier to entry.

May face regulatory hurdles or unclear policy frameworks depending on the region.

Requires reliable sources of feedstock (waste), necessitating robust supply chain management.

Contamination in waste streams can complicate the recovery process.

Tips for Implementation:

Prioritize high-value materials: Focus on materials with established recovery markets to ensure profitability.

Invest in technology: Implement technologies that improve sorting efficiency and reduce contamination.

Secure your feedstock: Develop partnerships with waste generators to ensure a consistent and reliable supply of materials.

Maintain material quality: Design recovery processes that preserve material quality through multiple recycling cycles.

Ensure traceability: Build traceability systems to demonstrate the provenance of recycled materials and build consumer trust.

Resource Recovery and Recycling is particularly suitable for businesses operating in industries with significant waste generation, such as manufacturing, packaging, and consumer goods. It's also an attractive option for companies committed to sustainability and seeking to reduce their environmental footprint. For e-commerce merchants, retail businesses, sustainability-conscious brands, and tech-savvy companies looking for growth opportunities, this model presents a pathway to enhance resource efficiency, reduce costs, and build a more resilient and sustainable business.

3. Product Life Extension

Product Life Extension represents a significant shift from the "take-make-dispose" mentality of the linear economy. This circular business model prioritizes maximizing the lifespan of products, keeping them in circulation and generating value for longer. It achieves this through several key strategies: design for durability, repairability, and modularity; offering robust maintenance and repair services; remanufacturing products to "as-new" condition; enabling upgrades through replaceable components; and implementing take-back programs to recapture products for refurbishment. Instead of pushing consumers towards frequent new purchases, this model encourages long-term ownership and product stewardship.

This approach offers a compelling alternative to the rapid obsolescence often seen in traditional business models. By designing products for durability and offering support for repairs and upgrades, companies can significantly reduce the need for frequent replacements. This not only benefits the environment by decreasing resource consumption and waste generation but also cultivates stronger customer relationships built on trust and quality.

Features of a Product Life Extension Model:

Design for Durability, Repairability, and Modularity: Products are engineered with robust materials and construction to withstand wear and tear. Modular designs allow for easy disassembly and replacement of individual components.

Repair and Maintenance Services: Manufacturers provide comprehensive repair and maintenance services, making it easy for consumers to keep their products in optimal condition.

Remanufacturing: Products reaching the end of their initial lifespan are collected and remanufactured to like-new condition, often using recovered components.

Upgradeable Components: Products can be updated with new features and functionalities through replaceable components, extending their relevance and usability over time.

Take-Back Programs: Companies offer take-back programs to collect used products for refurbishment, remanufacturing, or responsible recycling.

Pros:

Reduced Environmental Impact: Lower resource consumption and waste generation contribute to a smaller environmental footprint.

New Revenue Streams: Repair, maintenance, and upgrade services create new revenue opportunities beyond initial product sales.

Enhanced Brand Loyalty: Durable, high-quality products foster trust and build stronger customer relationships.

Lower Disposal Costs: Less frequent product replacement translates to lower disposal costs for both consumers and businesses.

Increased Accessibility: Refurbished products offer a more affordable entry point for consumers seeking quality goods.

Cons:

Potential for Lower Short-Term Sales: Longer product lifespans may initially impact sales volume of new products.

Increased Design Complexity: Designing for durability, repairability, and modularity can add complexity to the product development process.

Higher Initial Manufacturing Costs: Using durable materials and implementing modular designs can increase upfront manufacturing costs.

Cannibalization of New Product Sales: Refurbished offerings may compete with sales of new products.

Shift in Business Metrics: Success requires moving away from focusing solely on unit sales towards metrics like product lifespan and customer lifetime value.

Examples:

Patagonia: Known for its commitment to repairing and reselling used clothing, extending the life of its garments and promoting a circular economy.

Fairphone: Offers modular smartphones designed for repairability and longevity, empowering users to easily repair and upgrade their devices.

Caterpillar: Remanufactures heavy equipment components, giving them a second life and reducing the need for new production.

iFixit: Provides online repair guides and sells replacement parts, facilitating self-repair and extending product lifespans.

Vitsœ: Creates durable, adaptable furniture systems designed to last for generations.

Tips for Implementing Product Life Extension:

Design with Standardized, Replaceable Components: This simplifies repairs and upgrades.

Offer Transparent Repair Instructions and Reasonable Part Pricing: Empower customers to maintain their products.

Create Customer Loyalty Programs that Reward Long-Term Ownership: Incentivize customers to keep their products longer.

Consider Certification Programs for Refurbished Products: Build trust and assure quality.

Track Product Lifespans and Identify Common Failure Points: Continuously improve product design and durability.

When and Why to Use This Approach:

This model is particularly well-suited for e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and businesses seeking long-term growth. It’s ideal for products that are typically expensive, resource-intensive to produce, or have a high potential for upgrades and repairs. By embracing Product Life Extension, businesses can differentiate themselves through a commitment to quality, sustainability, and customer satisfaction, ultimately building a more resilient and responsible business model.

4. Sharing Platforms

Sharing platforms embody the core principles of the circular economy by maximizing the utilization of existing products and minimizing the need for new production. These platforms facilitate the shared use of assets that would otherwise sit idle, connecting owners with individuals seeking temporary access. This fosters a collaborative consumption model, reducing overall resource consumption and waste. By shifting from ownership to access, sharing platforms represent a powerful tool for businesses seeking sustainable growth while catering to the evolving needs of consumers.

How Sharing Platforms Work:

Sharing platforms function as digital marketplaces, connecting owners of underutilized assets with individuals willing to pay for temporary access. This is typically facilitated through a user-friendly interface where owners list their items, including details like availability, pricing, and usage guidelines. Potential users can then search for specific items, book them for a designated period, and often handle payment and communication directly through the platform. Digital technology plays a crucial role, enabling efficient matching of supply and demand, while integrated review and verification systems build trust and transparency between users.

Examples of Successful Implementation:

Airbnb: Revolutionized the hospitality industry by allowing individuals to rent out their homes or spare rooms, offering travelers unique accommodations and homeowners a source of income.

Turo & GetAround: These peer-to-peer car-sharing platforms enable car owners to rent out their vehicles when not in use, providing renters with affordable transportation options and maximizing vehicle utilization.

Tool Libraries: Community-based initiatives that allow members to borrow tools and equipment, reducing the need for individual ownership and promoting resource sharing within a neighborhood.

ShareGrid: Caters to the professional film and photography industry, allowing members to rent and share expensive equipment, fostering collaboration and reducing costs for filmmakers.

Peerby: Facilitates neighborhood borrowing of household items, promoting a sense of community and reducing consumption by allowing people to access items they need only occasionally.

Why Sharing Platforms Deserve a Place in the Circular Economy:

Sharing platforms directly address the issue of overconsumption and underutilization. By enabling access over ownership, they decrease the demand for new products, thereby reducing the environmental impact associated with manufacturing, distribution, and disposal. Furthermore, they empower individuals to generate income from underutilized assets, promoting economic efficiency and reducing waste.

Features and Benefits:

Digital platforms connecting owners and users: Streamlined access and efficient matching of supply and demand.

Trust mechanisms including reviews and verification: Builds trust and transparency between users.

Peer-to-peer or B2C sharing of underutilized assets: Offers flexibility and caters to various sharing models.

Integrated payment and booking systems: Simplifies transactions and ensures secure payments.

Asset tracking and monitoring technology (in some cases): Enhances security and accountability.

Pros:

Maximizes utilization of existing products.

Creates income opportunities from idle assets.

Reduces overall resource consumption by increasing sharing.

Provides access to products without the burden of ownership.

Creates community connections through collaborative consumption.

Cons:

Regulatory challenges in many jurisdictions.

Insurance and liability concerns.

Product wear and tear from multiple users.

Trust barriers between strangers.

Complex logistics of handovers and quality control.

Tips for Implementing a Sharing Platform Model:

Focus on high-value, low-utilization items: Target products that are expensive to purchase but used infrequently.

Invest in robust trust and verification systems: Prioritize user safety and build confidence within the community.

Create clear protocols for handling damages or conflicts: Establish clear guidelines to address potential issues.

Consider insurance partnerships to reduce user risk: Mitigate potential liabilities and provide peace of mind.

Design for easy onboarding to reduce friction to participation: A seamless user experience is crucial for adoption.

When and Why to Use This Approach:

Sharing platforms are particularly relevant for businesses operating in sectors with high capital expenditures, significant idle asset capacity, or where consumer demand is shifting towards access over ownership. This model is ideal for e-commerce merchants, retail businesses, sustainability-conscious brands, tech-savvy companies, and businesses seeking growth by tapping into the sharing economy. By embracing sharing platforms, businesses can contribute to a more sustainable future while unlocking new revenue streams and meeting evolving consumer preferences.

5. Circular Supply Chains

Circular supply chains represent a fundamental shift from the traditional linear "take-make-dispose" model. Instead of materials flowing through a system and ending up as waste, circular supply chains prioritize renewable, recyclable, or biodegradable inputs designed to be continually recirculated without losing quality. This model aims to eliminate the very concept of waste, ensuring materials remain in productive use indefinitely. Companies adopting this approach meticulously rethink their upstream supply chain, eliminating toxic substances and designing products for material recovery or safe biodegradation at the end of their lifespan.

This approach hinges on several key features: utilizing renewable, recycled, or biodegradable input materials; establishing closed material loops with robust recovery systems; eliminating toxins that hinder material cycling; ensuring transparency and traceability throughout the supply chain; and embracing biomimetic approaches to material design and selection. Learn more about Circular Supply Chains. This framework allows businesses to decouple economic growth from resource consumption, fostering a more sustainable and resilient future. Efficient inventory management is crucial for minimizing waste and maximizing resource utilization within a circular supply chain. For small businesses looking to optimize their inventory practices, consider exploring resources on inventory management for small business to boost profits and enhance sustainability.

Several companies have successfully implemented circular supply chain models. Adidas, in partnership with Parley for the Oceans, uses recycled ocean plastic to create shoes and apparel. Interface's Net-Works program sources discarded fishing nets to manufacture carpet tiles. Dell has established a closed-loop recycled plastic supply chain for its computers, while Renault operates a remanufacturing plant in Choisy-le-Roi, France, giving car parts a second life. Even tech giant Apple is working towards a closed-loop supply chain for rare earth elements in its products. These examples showcase the feasibility and potential of circularity across diverse industries.

Pros of adopting a circular supply chain:

Reduced exposure to resource price volatility and scarcity: By relying less on virgin materials, businesses become less susceptible to fluctuating market prices and supply disruptions.

Minimized waste management costs: Less waste generation translates directly into lower disposal and landfill costs.

Built-in resilience against supply chain disruptions: Diversifying material sources and utilizing recycled inputs strengthens a company's ability to withstand disruptions.

Reduced regulatory compliance costs: Circular practices often align with and even exceed environmental regulations, reducing the risk of penalties.

Marketing advantages through sustainability credentials: Consumers are increasingly conscious of environmental issues and favor brands committed to sustainability.

Cons of adopting a circular supply chain:

Potentially higher initial material costs: Sourcing recycled or bio-based materials can sometimes be more expensive than virgin materials, at least initially.

Extensive supplier engagement and education: Transitioning to a circular model requires significant collaboration and education throughout the supply chain.

Limited availability of certain circular materials at scale: Scaling up circular operations can be challenging if the required recycled or bio-based materials are not readily available in large quantities.

Complex logistics for material recovery: Setting up efficient collection and processing systems for end-of-life products can be logistically complex.

Possible need for product reformulation: Adapting products to incorporate recycled or bio-based materials may necessitate reformulations to maintain performance and quality.

Tips for implementing a circular supply chain:

Start with high-volume or environmentally significant materials: Focus initial efforts on materials that have the biggest environmental impact or represent a significant portion of your material usage.

Develop supplier assessment tools that evaluate circularity: Integrate circularity criteria into your supplier selection process.

Consider vertical integration for critical circular materials: Securing access to key recycled or bio-based materials might require vertical integration in certain cases.

Implement material passports to track components through lifecycles: Enhanced traceability improves material recovery and facilitates closed-loop systems.

Establish closed-loop pilot projects before scaling: Start small and test different approaches before implementing circularity across the entire supply chain.

Circular supply chains deserve a prominent place on any list of circular economy business models because they address the core issue of resource depletion and waste generation. By reimagining the flow of materials, businesses can unlock significant economic and environmental benefits. The growing popularity of frameworks like the Cradle to Cradle (C2C) certification system, the work of William McDonough and Michael Braungart, The Ellen MacArthur Foundation's CE100 network, and the Blue Economy concept promoted by Gunter Pauli further underscores the importance and momentum of this approach.

6. Product Redesign and Eco-Design

Product Redesign and Eco-Design represents a fundamental shift in how we approach product development. Instead of considering the end-of-life of a product as an afterthought, this model integrates circularity from the initial design phase. It focuses on minimizing waste, maximizing resource efficiency, and extending product lifespan through careful material selection, design for disassembly, and consideration of the entire product lifecycle. This proactive approach not only minimizes environmental impact but also unlocks new avenues for innovation and cost savings.

How it Works:

Eco-design involves a thorough reassessment of the materials, manufacturing processes, and overall design philosophy used to create a product. This includes:

Design for Disassembly and Material Separation: Products are engineered for easy disassembly, allowing for component reuse, repair, and efficient material recovery at the end of the product's life.

Material Selection Based on Recyclability and Regeneration Potential: Preference is given to recycled or renewable materials, as well as materials that can be easily recycled or biodegraded after use. Toxic substances are avoided entirely.

Modular Design Enabling Repair and Component Replacement: Modularity allows for the replacement of individual components rather than discarding the entire product, extending its lifespan and reducing waste.

Minimization of Material Diversity: Reducing the number of different materials used in a product simplifies recycling and material recovery processes.

Examples of Successful Implementation:

Several companies have successfully embraced eco-design principles:

Herman Miller's Aeron Chair: Designed for disassembly, making it easy to repair and recycle.

Fairphone: A modular smartphone designed for repairability and longevity, allowing users to easily replace components.

Apple: Increasingly incorporating recycled materials into its products and designing for disassembly to facilitate material recovery.

Freitag: Creates upcycled bags from reclaimed truck tarps, demonstrating the potential of using existing materials in innovative ways.

Steelcase's Think Chair: Designed with a minimal number of material types to simplify recycling.

Actionable Tips:

Implement Design Criteria Checklists for Circular Attributes: Develop a checklist that evaluates products against key circularity criteria, ensuring these considerations are integrated throughout the design process.

Conduct Lifecycle Analyses to Identify High-Impact Design Changes: Analyze the environmental impact of a product throughout its lifecycle to pinpoint areas where design modifications can have the biggest positive effect.

Train Designers in Circular Economy Principles: Equip your design team with the knowledge and skills necessary to implement circular design strategies effectively.

Consider Disassembly Time as a Key Performance Indicator: Set targets for disassembly time to encourage designs that facilitate efficient material recovery.

Create Material Libraries of Circular Alternatives: Compile a database of sustainable and recyclable materials to guide material selection during the design process.

When and Why to Use This Approach:

This approach is particularly relevant for businesses seeking to:

Minimize Environmental Impact: Eco-design directly addresses the environmental footprint of a product.

Reduce Costs: Material efficiency and reduced waste can lead to significant cost savings.

Comply with Evolving Environmental Regulations: Eco-design helps businesses stay ahead of increasingly stringent environmental regulations.

Enhance Brand Reputation: Demonstrating a commitment to sustainability can strengthen brand image and attract environmentally conscious consumers.

Create Products with Higher End-of-Life Value: Designing for disassembly and material recovery increases the residual value of products at the end of their life.

Pros and Cons:

Pros:

Addresses circular challenges at the source.

Can reduce manufacturing costs through material efficiency.

Improves compliance with evolving environmental regulations.

Creates products with higher end-of-life value.

Often results in a superior customer experience through thoughtful design.

Cons:

May require significant upfront R&D investment.

Can necessitate retooling of manufacturing processes.

Sometimes creates tension with traditional aesthetic expectations.

May involve tradeoffs in certain performance characteristics.

Requires deep expertise in materials science and design.

Popularized By:

William McDonough (Cradle to Cradle), Janine Benyus (Biomimicry), IDEO's circular design methodology, and TU Delft's Design for Sustainability program have all been instrumental in popularizing and developing the principles of eco-design.

Product Redesign and Eco-design deserves its place on this list because it represents the most proactive and impactful approach to achieving a circular economy. By addressing circularity at the design stage, businesses can fundamentally transform their product development processes and create a more sustainable future. It’s a critical strategy for any organization seeking to minimize waste, maximize resource efficiency, and build a truly sustainable business model.

7. Take-Back Programs and Reverse Logistics

Take-Back Programs and Reverse Logistics represent a crucial element of the circular economy, shifting the traditional linear "take-make-dispose" model to a closed-loop system. This business model focuses on recovering products from consumers after their intended use, enabling businesses to recapture value from these items and minimize waste. By implementing efficient reverse logistics networks – systems as sophisticated as their forward supply chain counterparts – companies can effectively manage the return flow of products to appropriate facilities for remanufacturing, refurbishment, component harvesting, or material recovery. This approach takes responsibility for the entire product lifecycle, emphasizing resource efficiency and minimizing environmental impact.

How it Works:

Take-back programs rely on establishing convenient channels for customers to return used products. This can involve designated collection points, pre-paid shipping labels, or even pick-up services. Incentives such as discounts on future purchases, store credit, or even cash refunds encourage customer participation. Once collected, returned products are sorted and evaluated based on their condition. Items suitable for resale or refurbishment are processed accordingly, while others might be disassembled for component recovery or material recycling. The entire process demands a robust reverse logistics network that manages the flow of returned products efficiently and cost-effectively.

Successful Implementations:

Several companies have successfully implemented take-back programs, demonstrating the viability and benefits of this model:

Apple: Offers trade-in programs and recycling initiatives for its devices, allowing customers to receive credit towards new purchases or responsible recycling of older models.

H&M: Runs a garment collecting initiative, accepting unwanted textiles from any brand in exchange for a discount voucher, promoting textile recycling and reducing landfill waste.

Nespresso: Provides recycling bags and collection points for used coffee capsules, enabling the recovery of valuable aluminum and coffee grounds for reuse.

DeWalt: Operates a battery recycling program, facilitating the responsible disposal and recycling of power tool batteries, minimizing environmental hazards.

Best Buy: Offers an electronics take-back service, accepting a wide range of electronics for recycling, contributing to responsible e-waste management.

Actionable Tips for Implementation:

Convenience is Key: Make returning products as easy as the initial purchase experience. Offer multiple return options, including pre-paid shipping labels, drop-off locations, and scheduled pick-ups.

Strategic Partnerships: Collaborate with retail partners to establish convenient collection points, expanding your reach and accessibility for customers.

Technology Integration: Leverage technology to track and trace returned items, providing transparency and efficiency throughout the reverse logistics process.

Design for Disassembly: Consider product design that facilitates easy disassembly and component separation, optimizing material recovery and reuse.

Incentivize Participation: Offer compelling incentives aligned with product value, encouraging customer engagement and maximizing return rates.

When and Why to Use This Approach:

Take-back programs are particularly relevant for businesses dealing with:

High-value products: Recapturing value from expensive electronics, appliances, or equipment through refurbishment and resale.

Products with hazardous components: Ensuring responsible disposal and recycling of items containing batteries, chemicals, or other hazardous materials.

Products with long lifespans: Extending the useful life of durable goods through repair, refurbishment, and component reuse.

Brands committed to sustainability: Demonstrating environmental responsibility and building a positive brand image by closing the loop on product lifecycles.

Pros & Cons:

Pros:

Secures reliable streams of materials and components, reducing reliance on virgin resources.

Creates valuable customer touchpoints for relationship building and brand loyalty.

Reduces costs through component reuse and material recovery.

Provides valuable data on product performance and failure modes for future product development.

Can fulfill extended producer responsibility (EPR) requirements and avoid potential penalties.

Cons:

Significant logistical complexity in managing reverse supply chains.

Substantial investment in reverse logistics infrastructure.

Unpredictable quality and timing of product returns.

Consumer education and participation challenges.

Storage and handling costs for returned items.

Why This Deserves Its Place on the List:

Take-back programs represent a fundamental shift towards a circular economy, enabling businesses to move beyond linear consumption patterns and embrace resource efficiency. By reclaiming valuable materials and components, these programs contribute to waste reduction, minimize environmental impact, and create new revenue streams. They also strengthen customer relationships and enhance brand reputation by demonstrating a commitment to sustainability. In a world increasingly focused on resource scarcity and environmental responsibility, take-back programs are not just a trend, but a necessary evolution in business practices.

8. By-Product Synergy and Industrial Symbiosis

By-product synergy and industrial symbiosis represent a powerful circular economy model that transforms waste into valuable resources. This approach mimics natural ecosystems, where waste from one organism becomes food for another. In a business context, it involves establishing partnerships where one company's by-products or waste streams become another's raw materials. This creates closed-loop systems, minimizing waste disposal and reducing reliance on virgin resources.

How it Works:

This model hinges on identifying and matching complementary businesses. It begins with a thorough analysis of a company’s waste streams, characterizing their composition, volume, and consistency. Then, through platforms and networks, these waste streams are matched with companies that can utilize them as inputs in their processes. This often involves geographic clustering of complementary businesses to minimize transportation costs and logistical challenges. Transformation processes may be required to convert by-products into usable inputs, adding value and creating further economic opportunities.

Features of By-Product Synergy and Industrial Symbiosis:

Waste stream mapping and characterization: Detailed analysis of waste composition and volume.

Cross-industry material matching platforms: Online and offline networks facilitating connections between businesses.

Geographic clustering of complementary businesses: Reduces transport costs and emissions.

Resource exchange networks: Formal or informal agreements for the transfer of materials, energy, and water.

Transformation processes: Converting by-products into usable inputs.

Examples of Successful Implementation:

Kalundborg Symbiosis (Denmark): This world-renowned example connects a power plant, refinery, pharmaceutical company, gypsum board manufacturer, and other businesses in a closed-loop system. Waste heat, steam, gypsum, fly ash, and other by-products are exchanged and utilized, creating significant economic and environmental benefits.

Guitang Group (China): This sugarcane processing company utilizes its by-products (bagasse, molasses) to produce paper, alcohol, and cement, demonstrating a comprehensive approach to resource utilization within a single business.

Brewery Spent Grain: Spent grain from breweries, a significant by-product, is often repurposed as animal feed, a valuable resource for farmers.

Steel Slag: Slag, a by-product of steel production, can be used as a substitute for cement in concrete, reducing the need for virgin materials and minimizing waste.

CO2 Capture and Utilization: CO2 captured from industrial processes can be used to enrich greenhouses, enhancing plant growth and reducing atmospheric emissions.

Pros:

Creates value from waste materials: Turns a cost center (waste disposal) into a revenue stream.

Reduces disposal costs and environmental impacts: Minimizes landfill usage and pollution.

Decreases raw material costs for recipient companies: Provides access to cheaper, locally sourced materials.

Builds resilient local business networks: Fosters collaboration and strengthens regional economies.

Often reduces overall energy and water consumption: Improves resource efficiency throughout the supply chain.

Cons:

Dependency risks: Changes in partner businesses (closure, change in production) can disrupt supply chains.

Quality consistency challenges: By-product quality can vary, requiring careful monitoring and potentially pre-processing.

Logistical complexities: Transporting and handling by-products can be complex and costly.

Regulatory barriers: Regulations surrounding waste transportation and use can be complex and vary by location.

Process modifications: Recipient companies may need to modify their processes to utilize by-products.

Tips for Implementation:

Start with waste streams with consistent quality and volume: This simplifies initial integration and reduces complexity.

Join or create local industrial ecology networks: These networks facilitate connections and information sharing.

Consider third-party intermediaries: Intermediaries can process or standardize by-products, reducing complexity for partners.

Develop contingency plans for supply disruptions: Mitigate risks associated with reliance on by-product streams.

Document economic and environmental benefits for all partners: This helps to solidify partnerships and demonstrate the value of the approach.

Why By-Product Synergy Deserves its Place:

This model embodies the core principles of the circular economy, turning waste into a resource and creating mutually beneficial relationships between businesses. It offers a powerful pathway towards more sustainable and resilient industrial practices, driving both economic and environmental benefits. By minimizing waste, reducing reliance on virgin resources, and fostering local collaboration, by-product synergy offers a compelling model for businesses seeking growth while contributing to a more sustainable future. It's particularly relevant for e-commerce merchants, retail businesses, sustainability-conscious brands, and tech-savvy companies looking to optimize their supply chains and reduce their environmental footprint. While challenges exist, the potential rewards of this model make it a crucial strategy for businesses striving for a circular future.

9. Digital Platforms for Material Tracking and Trading

The circular economy thrives on efficient resource utilization, and one of the most promising avenues for achieving this is through digital platforms for material tracking and trading. These platforms leverage technology to create unprecedented transparency and traceability throughout the supply chain, facilitating the efficient sharing, trading, and recycling of resources. This approach fundamentally reimagines waste as a valuable resource, promoting a shift from a linear "take-make-dispose" model to a circular one.

How it Works:

These platforms function by digitizing material information, effectively creating a "digital passport" for each material or component. This passport can record crucial details like composition, origin, processing history, and even environmental impact data. Blockchain or distributed ledger technology (DLT) is often employed to ensure data integrity and immutability, building trust and transparency amongst stakeholders. This digital thread enables businesses to track materials throughout their lifecycle, from raw material extraction to end-of-life management. Online marketplaces are then created to facilitate the exchange of secondary materials and components, connecting waste generators with potential users. Some platforms even incorporate IoT sensors to monitor product condition and location in real-time, and AI-powered algorithms to match waste streams with suitable reuse or recycling options.

Examples of Successful Implementation:

Excess Materials Exchange: This platform connects businesses with surplus materials to others who can use them, diverting valuable resources from landfills.

Circulor: Uses blockchain technology to track the provenance of raw materials, particularly in complex supply chains like those for ethical minerals, enhancing transparency and accountability.

MaterialTrader: Provides an online marketplace specifically designed for trading secondary materials, simplifying the process of buying and selling recycled or surplus resources.

Rubicon: Offers a digital platform for waste management, streamlining operations and promoting recycling through data analytics and improved logistics.

Provenance: Leverages blockchain to build trust and transparency in supply chains by allowing consumers to trace the origin and journey of products.

Actionable Tips for Implementation:

Start with High-Value Materials: Initially focus on materials with established recovery markets to maximize impact and demonstrate value quickly.

Develop Clear Data Standards: Collaboration and standardization of data formats are crucial for interoperability and seamless data exchange across different platforms and industries.

Incentivize Accurate Data Input: Implement mechanisms to encourage accurate and consistent data entry and maintenance, ensuring data quality.

User-Friendly Interfaces: Design intuitive and easy-to-use interfaces to minimize adoption barriers and encourage widespread participation.

System Integration: Integrate the digital platform with existing Enterprise Resource Planning (ERP) and material management systems for streamlined data flow and operational efficiency.

When and Why to Use This Approach:

This approach is particularly valuable for businesses committed to circular economy principles and seeking to optimize resource utilization, reduce waste, and enhance supply chain transparency. It's especially relevant for industries dealing with complex supply chains, high-value materials, or significant waste streams. E-commerce merchants, retail businesses, sustainability-conscious brands, and tech-savvy companies can all benefit from implementing these platforms.

Pros:

Increased transparency throughout material lifecycles

Reduced transaction costs for secondary material markets

Enhanced trust through verified material information

More precise material sorting and recycling

Creation of accessible marketplaces for materials that would otherwise be wasted

Cons:

Requires widespread adoption to achieve network effects

Data standardization challenges across industries

Privacy and competitive concerns with data sharing

Technical infrastructure requirements

Potential resistance from established waste management industries

Popularized By:

IBM's blockchain supply chain initiatives

Ken Webster (Ellen MacArthur Foundation)

World Economic Forum's Accelerating Digital Traceability program

Circle Economy's digital initiatives

This model deserves its place on the list because it represents a fundamental shift in how we manage resources. By leveraging the power of digital technology, these platforms unlock the potential of the circular economy, driving both environmental and economic benefits. They empower businesses to track, trace, and trade materials with unprecedented efficiency, ultimately reducing waste, optimizing resource use, and building a more sustainable future.

10. Product-Service Bundles

Product-service bundles represent a compelling step towards a circular economy for businesses rooted in traditional product sales. This hybrid model combines the familiar act of product ownership with a suite of integrated services that incentivize product longevity and responsible end-of-life management. Essentially, customers still buy the product, but the relationship with the company extends beyond the initial purchase through ongoing service agreements. This ongoing connection is the key to driving circularity.

How it Works:

Product-service bundles weave together product sales with services like maintenance, repair, upgrades, and eventual product recovery. This encourages customers to keep products in use for longer periods, reducing the demand for new products and minimizing waste. The service component creates continuous revenue streams and strengthens customer relationships, fostering loyalty and providing valuable feedback loops for product development.

Successful Implementations:

Several companies have demonstrated the effectiveness of product-service bundles:

Apple's AppleCare+: This extended warranty service provides repair and replacement coverage, encouraging repair over replacement and extending the lifespan of Apple devices.

Whirlpool's Appliance Service Plans: These plans offer preventative maintenance and repairs, keeping appliances running smoothly and reducing the need for premature replacements.

Patagonia's Repair Services: Patagonia actively encourages repair by offering repair services for their clothing, aligning with their commitment to product longevity and environmental responsibility.

Interface's ReEntry Program: This program facilitates the recycling of used Interface carpet tiles, ensuring valuable materials are recovered and repurposed.

HP Instant Ink: This subscription service automatically delivers ink cartridges to customers, simplifying printer maintenance and promoting responsible cartridge recycling.

Actionable Tips:

Design for Serviceability: Consider repairability and modularity from the product design stage. Easy-to-repair products are crucial for this model.

Train Your Sales Team: Equip your sales force to effectively communicate the value proposition of bundled services and address customer concerns.

Tiered Service Offerings: Offer a range of service packages to cater to different customer needs and budgets, maximizing accessibility and appeal.

Feedback Loop: Use service interactions as opportunities to gather valuable feedback on product performance and identify areas for improvement.

Track Key Metrics: Monitor service attachment rates and customer retention to gauge the effectiveness of your bundled offerings and identify areas for optimization.

When and Why to Use This Approach:

Product-service bundles are particularly well-suited for businesses looking to transition towards a more circular model without completely abandoning their existing product-focused infrastructure. It's an ideal strategy for companies with durable goods where ongoing maintenance and repair are feasible and valuable to customers. This approach provides a gentler on-ramp to the circular economy compared to more radical models like Product-as-a-Service.

Pros:

Recurring Revenue: Creates stable, ongoing revenue streams beyond the initial product sale.

Smoother Transition: Offers a manageable transition for traditional product companies entering the circular economy.

Stronger Customer Relationships: Fosters loyalty and engagement through ongoing service interactions.

Valuable Product Insights: Provides data on product performance and failure modes, informing future design and development.

Predictable Cash Flow: Provides a more predictable cash flow compared to pure service models.

Cons:

Less Resource-Efficient: Not as resource-efficient as full Product-as-a-Service models, as it still relies on product ownership.

Service Infrastructure: Requires development of service capabilities in addition to manufacturing.

Sales Tension: May create tension between promoting product durability and driving new product sales.

Scaling Challenges: Service logistics can be complex and challenging to scale effectively.

Pricing Complexity: Requires careful balancing of product and service pricing to ensure profitability and customer appeal.

Popularized By:

The concept of product-service bundles has been championed by companies like Ricoh (Comet Circle), Xerox (document management services), and Interface (Mission Zero initiative). Certified B Corporations, with their emphasis on product longevity and social responsibility, also frequently employ this model.

Product-service bundles deserve a place on this list because they offer a practical and effective pathway for businesses to embrace circularity. By combining product ownership with ongoing service, companies can build stronger customer relationships, generate recurring revenue, and contribute to a more sustainable future.

Circular Economy Business Models: 10-Point Strategy Comparison

Business Model | 🔄 Complexity | ⚡ Resources | 📊 Outcomes | 💡 Use Cases | ⭐ Advantages |

|---|---|---|---|---|---|

Product as a Service (PaaS) | High – Complex maintenance & logistics require integration | High – Significant capital and tech systems (IoT, monitoring) | Continuous revenue streams and valuable usage data | B2B markets and subscription-based services | Strong customer relationships and sustainable profitability |

Resource Recovery and Recycling | Moderate – Needs advanced processing and sorting systems | High – Investment in processing facilities and quality controls | Reduced reliance on virgin materials and waste valorization | Waste management and manufacturing sectors | Cost advantages through resource efficiency |

Product Life Extension | Moderate – Designing for durability and maintenance adds complexity | Moderate – Increased R&D and manufacturing costs for robust design | Extended product lifespan with lower waste generation | Durable goods like electronics and apparel | Enhanced brand loyalty and reduced environmental impact |

Sharing Platforms | Moderate – Digital platform with trust and verification systems | Low to moderate – Primarily digital investment, minimal physical assets | Optimized asset utilization and income from idle resources | Peer-to-peer rentals and collaborative consumption | Maximizes utilization and builds community connections |

Circular Supply Chains | High – Requires extensive supplier engagement and supply chain redesign | Moderate to high – Potential premium costs for sustainable materials | Resilient supply chains with reduced resource volatility | Companies with complex, global supply chains | Sustainability credentials and reduced regulatory risks |

Product Redesign and Eco-Design | High – Significant R&D and potential retooling of manufacturing processes | High – Substantial investment in design innovation and materials science | Improved recyclability, reduced material use, and long-lasting products | Eco-conscious brands and product innovation centers | Lower lifecycle costs and enhanced end-of-life product value |

Take-Back Programs and Reverse Logistics | High – Complex logistics and reverse supply chain management | High – Investment in collection, transportation, and processing systems | Reliable material recovery and deeper customer interaction insights | Consumer goods, electronics, and appliances | Secures component reuse and reinforces extended producer responsibility |

By-Product Synergy and Industrial Symbiosis | Moderate – Coordination among multiple partner businesses | Moderate – Dependent on local clustering and process adjustments | Converts waste into value with cost savings and lower disposal needs | Industrial clusters and local industrial ecosystems | Lowers disposal costs and fosters efficient resource exchange |

Digital Platforms for Material Tracking and Trading | Moderate – Requires tech integration and data standardization | Moderate – Investment in digital infrastructure and data management | Enhanced transparency and reduced transaction costs in material markets | Material marketplaces and modern supply chain management | Improved traceability and efficient matching of supply and demand |

Product-Service Bundles | Moderate – Integration of product sales with service systems | Moderate – Balanced investment in product and service capabilities | Ongoing service revenue streams and smoother cash flow compared to pure sales | Traditional product companies transitioning to service models | Strengthens customer relationships and enhances overall product value |

Embracing the Future: Circularity's Impact

The circular economy represents a fundamental shift from the traditional "take-make-dispose" linear model. This article explored ten key circular business models, from Product as a Service and resource recovery to innovative digital platforms and product-service bundles. The core takeaway is that circularity fosters resilience, unlocks new revenue streams, and minimizes environmental impact by maximizing resource utilization and minimizing waste. Mastering these approaches is crucial for businesses seeking long-term growth in a world increasingly focused on sustainability. By embracing circularity, companies can gain a competitive edge, attract environmentally conscious consumers, and contribute to a healthier planet. This transition requires a proactive approach, but the rewards – both economic and environmental – are significant. It’s time to move beyond simply mitigating negative impacts and actively create positive change through circularity.

Ready to implement circular economy principles into your business and optimize your resource management? Sharpei helps businesses track, manage, and optimize their material flows, facilitating the transition to a circular economy. Visit Sharpei to learn more and explore how we can help you embrace a more sustainable and profitable future.

Related posts

Ready To Join The Circular Movement?

United for a smarter shopping experience and a better planet